- Corten differs from regular steel in the following ways:

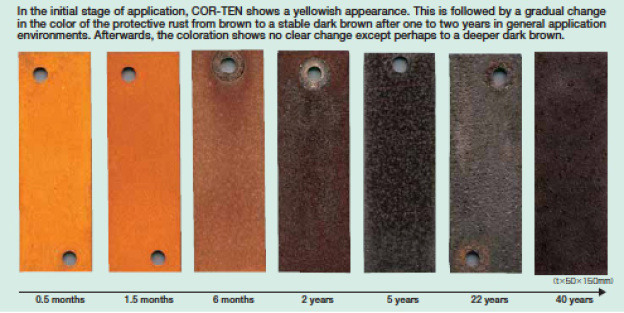

- Corten has a surface layer that oxidizes. Once that surface layer has completed the oxidization process, it self-seals, protecting the material underneath.

- Regular steel does not have this self-sealing property. It will rust all the way through. Yes, it will.

- Cor-ten is a trade name (trademarked). It is like calling tissue paper “Kleenex”. It is also commonly known as Corten and weathering steel.

- Corten steel is VERY reactive with certain alloys and products. For example, Corten steel cannot be painted. Painting Corten will compromise the integrity of the material, and also defeats the entire purpose of the product.

- There are only two mass-produced sealants that are Corten steel-compatible. These are mostly used for interior Corten applications.

- Corten steel is only compatible with specific metals. Guess what happens if it’s paired with something it shouldn’t be?

- If welding Corten steel using improper wire, your welds will fail with certainty. It is important that your weld points weather at a similar rate than the base material and hold up just as well. Special welding techniques and materials are needed.

RSS Feed

RSS Feed